Good practice for sand mining

Tom Bide and Clive Mitchell outline how BGS is working on geoscience-led solutions for the global issue of sand mining.

24/10/2023

Rapidly increasing demand for sand in many countries, combined with little or no governance, has resulted in sand mining causing wide ranging negative environmental and economic impacts. This is driven by the increasing demand for concrete due to urban growth and the need for good-quality housing and infrastructure in many parts of the world. BGS is working on geoscience-led solutions to this problem as part of the International Geoscience Research and Development (IGRD) project. We covered how we are going about this in our first blog, Living in a world made of sand.

To enable the public, researchers, geological surveys, regulators, industry and consumers to understand the issues around sand mining, the BGS project team worked with Sarah Hannis, a freelance illustrator, to create images that capture the current situation and potential solutions. These aim to show how geoscience data and information can be used for the monitoring and management of sand resources.

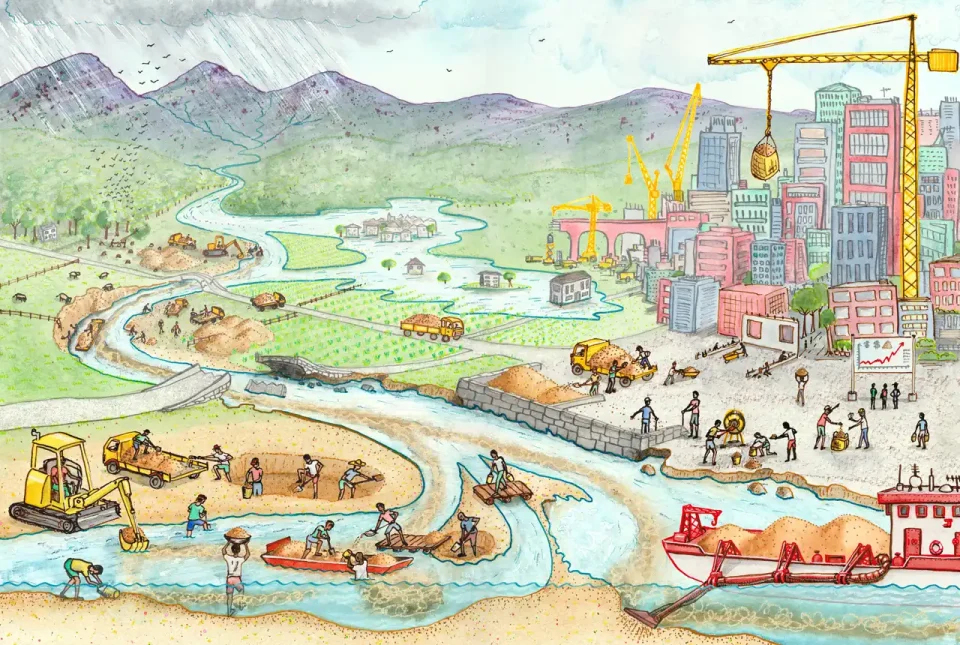

The current situation

The current sand mining situation. © Sarah Hannis Illustration.

In many countries, large-scale extraction of sand from rivers and the nearshore environment causes:

- increased erosion of banks and beaches

- damage to infrastructure

- harm to water quality, farmland and biodiversity

- increased risk of flooding

Sand supply is often inadequate to meet future needs, causing price fluctuations and stockpiling. There is little or no consideration by the consumer of where this essential building raw material comes from, no transparency in the supply chain, and no linkage between urban planning and those with responsibility for managing sand resources. in many places this is a supply system that is either breaking down or has effectively already broken down, in many places.

In the following illustrations, we show examples of good practice that could be considered to help break out of this unsustainable scenario.

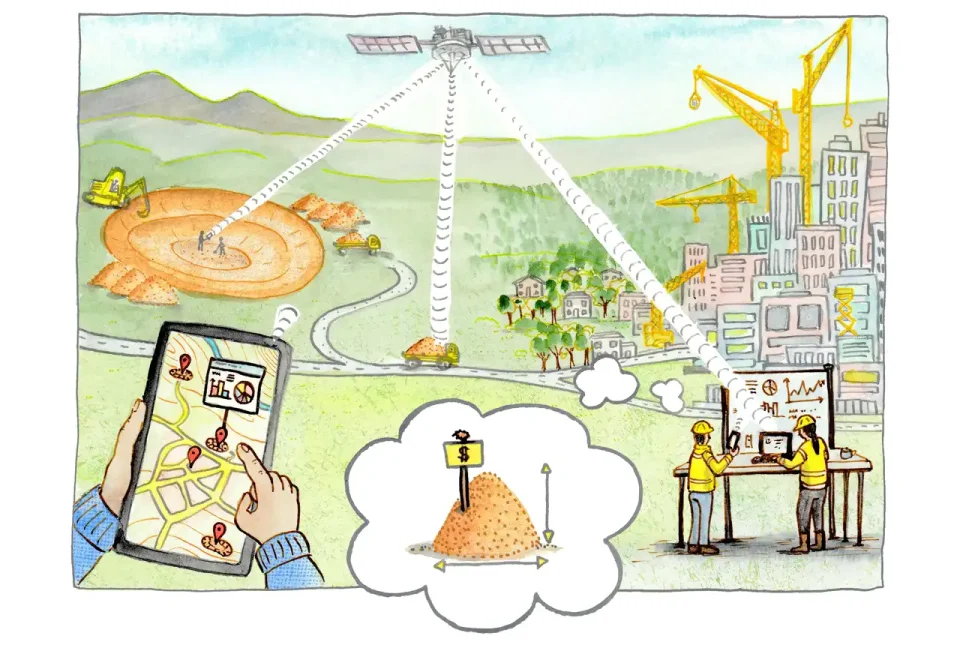

Monitoring

Monitoring sand remotely. © Sarah Hannis Illustration.

The initial steps in controlling extraction and increasing supply from more sustainable sources are:

- better understanding of how much sand there is

- understanding how much sand is being produced

- knowing where the sand comes from

- knowing where the sand is used

Traditionally, surveys of the sand industry by regulatory authorities are a key source of data. Instead of surveying, which can be expensive, time consuming and require a strong regulatory regime, the sand team at BGS has been using remote sensing, a more accessible, alternative, way to monitor the activities of the sand industry.

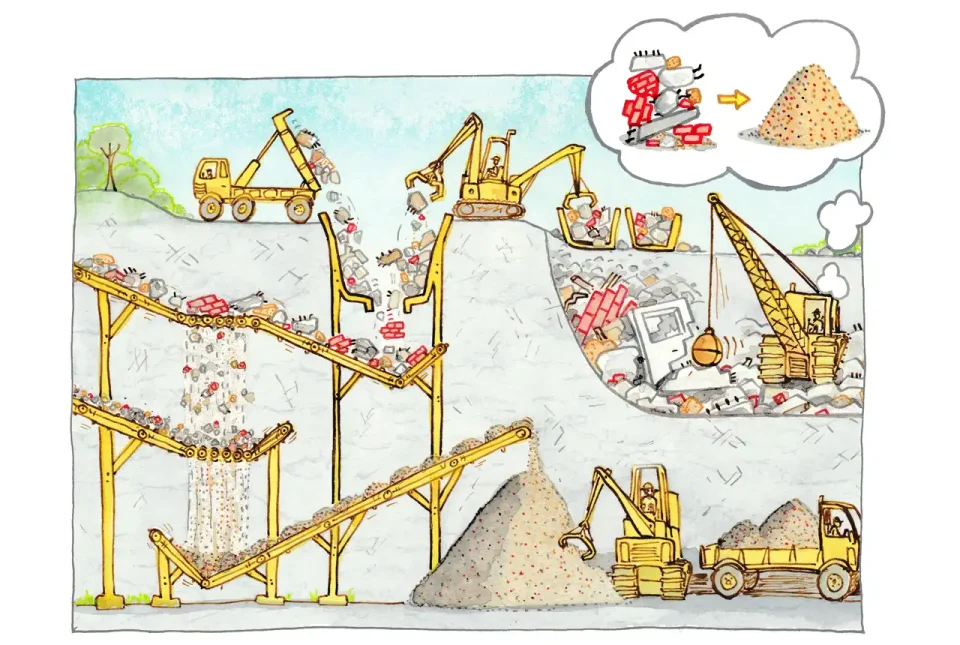

Recycling

Recycling sand. © Sarah Hannis Illustration.

Moving towards a circular economy is a key part of any solution to reduce the environmental impact of natural resource consumption. Enabling a circular economy requires a clear understanding of the material supply chain as well as collaboration between planners, consumers and producers. Utilisation of construction, excavation and demolition waste (often referred to as CDEW) may be a viable alternative to natural sand, as may recycling of other products, such as crushed glass. Re-use of modular building material may also help reduce the demand for natural sand.

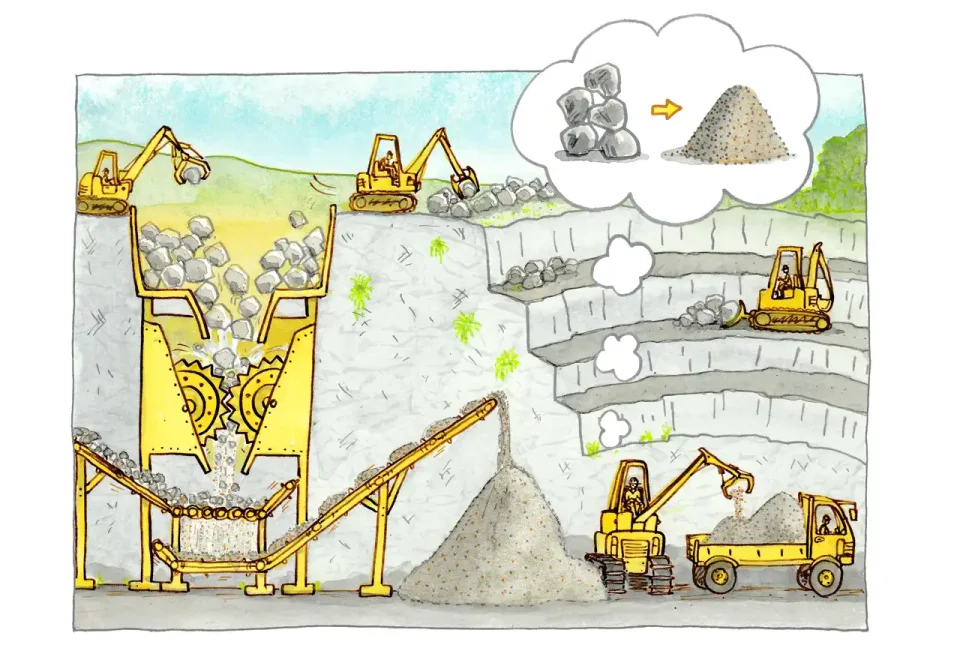

Use of alternative primary materials

The viability of using alternative building materials. © Sarah Hannis Illustration.

One of the main alternatives to natural sand is ‘manufactured sand’, which is produced from the crushing of hard rocks. This can be a primary product or a by-product from mine (sometimes known as ore sand) and quarry waste. Manufactured sand has similar physical and chemical properties to natural sand. It is also easier to manage the environmental effects from quarry sites, which are often located far from the sensitive environments where river and beach sand is found. However, consideration needs to be given to the increased energy often required to produce manufactured sand.

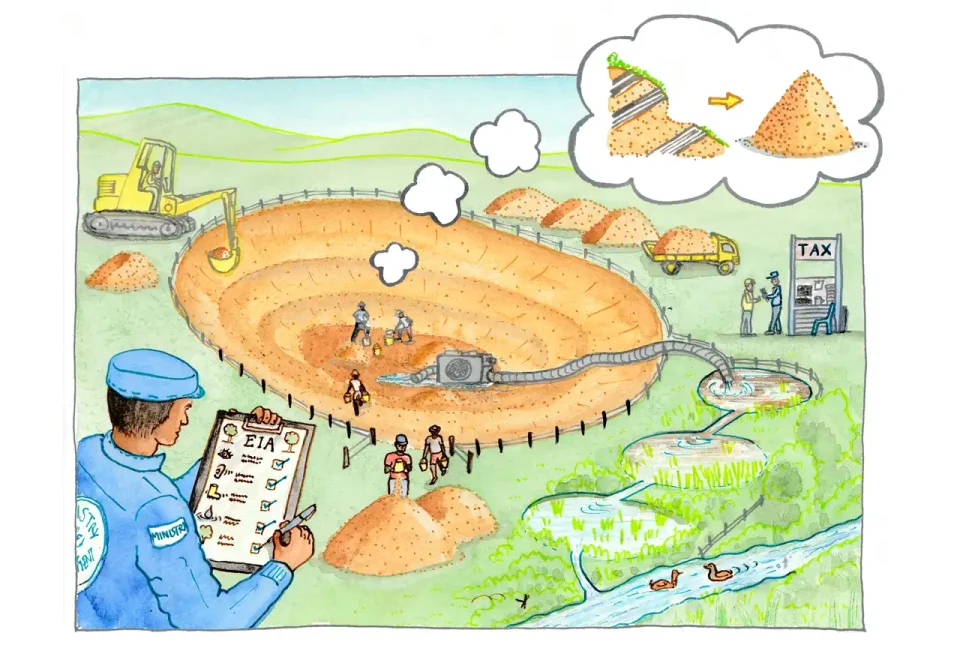

Sourcing of natural sands

Responsible sourcing of natural sand. © Sarah Hannis Illustration.

Mining of natural sand should be targeted at ‘fossil’ or geological deposits formed from the sediments of ancient river systems or offshore environments. These can be located well away from active water courses, beaches and marine environments. Extraction needs to be carefully regulated; one way of achieving this is to implement tax or royalties to ensure local administrations take an active interest in extraction and the sand resource is valued.

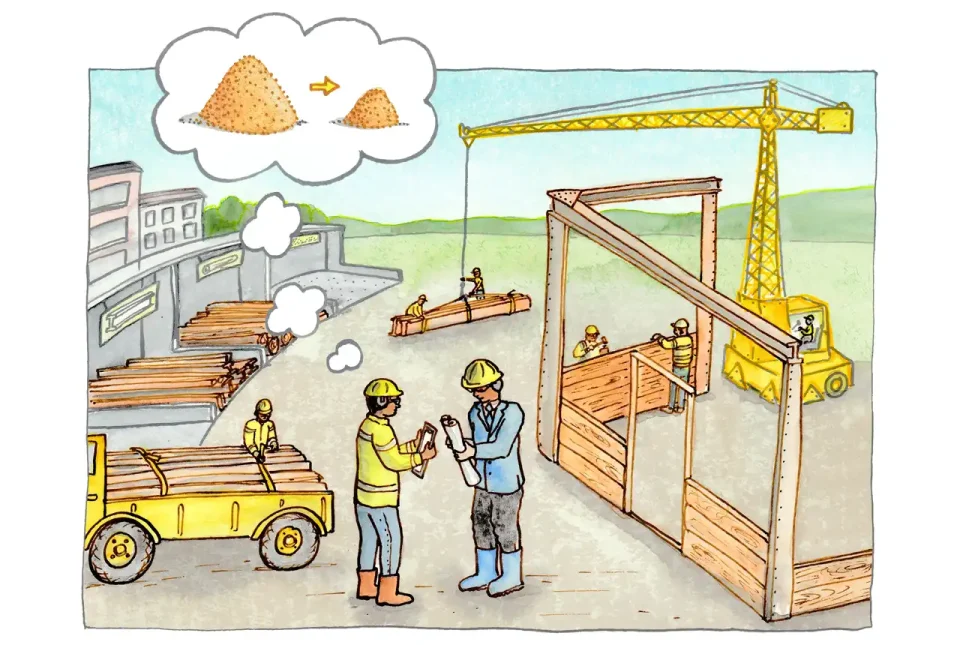

Reduction of use

The reduction of sand use. © Sarah Hannis Illustration.

Reducing demand for, and therefore consumption of, sand will help to alleviate the pressure on sensitive environments. Reducing the use of concrete is one way to reduce our reliance on sand.

There are many ways to reduce the use of concrete. In some applications, timber may be a sustainable alternative; increased use of steel and glass in construction may also reduce demand for concrete. Reduction can also be achieved by smarter design. For instance, reducing the size of floor spans or constructing smaller buildings helps to reduce material consumption.

Using these illustrations

All illustrations are available to re-use for non-commercial purposes relating to the promotion of good practice for sand mining provided the source is acknowledged and the copyright notice accompanying the illustration is retained.

High-resolution versions of the images are available to download.

About the authors

Tom Bide

Minerals geoscientist

Clive Mitchell

Industrial minerals geologist

Relative topics

Latest blogs

AI and Earth observation: BGS visits the European Space Agency

02/07/2025

The newest artificial intelligence for earth science: how ESA and NASA are using AI to understand our planet.

Geology sans frontières

24/04/2025

Geology doesn’t stop at international borders, so BGS is working with neighbouring geological surveys and research institutes to solve common problems with the geology they share.

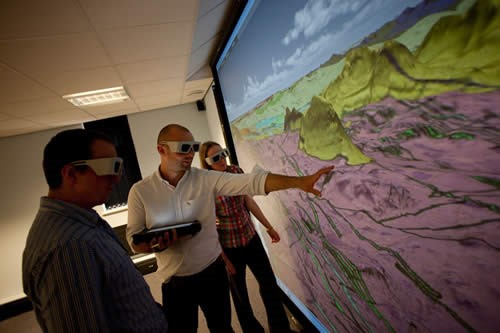

Celebrating 20 years of virtual reality innovation at BGS

08/04/2025

Twenty years after its installation, BGS Visualisation Systems lead Bruce Napier reflects on our cutting-edge virtual reality suite and looks forward to new possibilities.

Exploring Scotland’s hidden energy potential with geology and geophysics: fieldwork in the Cairngorms

31/03/2025

BUFI student Innes Campbell discusses his research on Scotland’s radiothermal granites and how a fieldtrip with BGS helped further explore the subject.

Could underground disposal of carbon dioxide help to reduce India’s emissions?

28/01/2025

BGS geologists have partnered with research institutes in India to explore the potential for carbon capture and storage, with an emphasis on storage.

Carbon and oxygen isotope analysis of carbonates and the development of new reference materials

18/12/2024

Dr Charlotte Hipkiss and Kotryna Savickaite explore the importance of standard analysis when testing carbon and oxygen samples.

Studying oxygen isotopes in sediments from Rutland Water Nature Reserve

20/11/2024

Chris Bengt visited Rutland Water as part of a project to determine human impact and environmental change in lake sediments.

Celebrating 25 years of technical excellence at the BGS Inorganic Geochemistry Facility

08/11/2024

The ISO/IEC 17025 accreditation is evidence of technical excellence and reliability, and a mark of quality assurance.

Electromagnetic geophysics in Japan: a conference experience

23/10/2024

Juliane Huebert took in the fascinating sights of Beppu, Japan, while at a geophysics conference that uses electromagnetic fields to look deep into the Earth and beyond.

Exploring the role of stable isotope geochemistry in nuclear forensics

09/10/2024

Paulina Baranowska introduces her PhD research investigating the use of oxygen isotopes as a nuclear forensic signature.

BGS collaborates with Icelandic colleagues to assess windfarm suitability

03/10/2024

Iceland’s offshore geology, geomorphology and climate present all the elements required for renewable energy resources.

Mining sand sustainably in The Gambia

17/09/2024

BGS geologists Tom Bide and Clive Mitchell travelled to The Gambia as part of our ongoing work aiming to reduce the impact of sand mining.