The Transport Properties and Fracture Physics Research Laboratories at the BGS are led by Caroline Graham and Robert Cuss, respectively, and are part of the Fluid and Rock Processes Laboratory Cluster. Research in the Transport Properties Research Laboratory (TPRL) and the Fracture Physics Laboratory (FPL) focuses on understanding the mechanisms and processes governing the movement of fluids (water, gas and solutes) and the deformation of rock in the subsurface, specialising in the measurement of properties in ultra-low permeability materials. Thirty years of development in this field has led to high-precision techniques, allowing exceptionally small amounts of flow to be measured where conventional techniques can be unsuccessful. As such, the TPRL and FPL are able to investigate the long-term properties of rocks that act as ‘seals’ to fluid, on geological timescales.

Laboratory capability

With careful attention to experimental design, choice of instrumentation, calibration and regulation of testing conditions, the laboratories are able to quantify key properties for intact, fractured and flow along interfaces for low permeability materials.

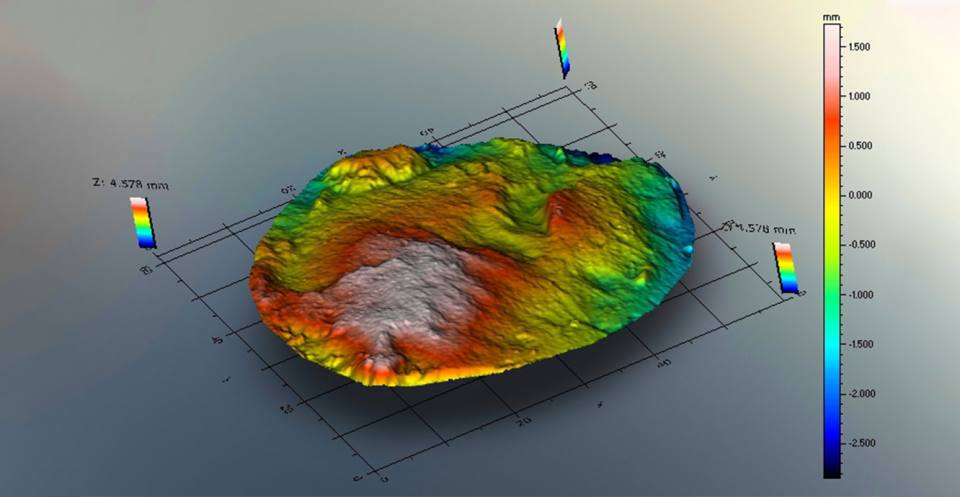

- Apparatus and experimental methodologies are custom designed to meet the precise requirements of the client and work programme.

- Experiments can be performed on intact or fractured rock, as well as interfaces between neighbouring materials.

- Experiments are performed under simulated downhole stress, pore pressure, temperature, and chemical conditions using triaxial, isotropic (hydrostatic) or constant-volume cells.

- High accuracy, heavy duty shear box systems have been developed to examine fracture, fault and interfacial flow.

- Apparatus is assembled in a constant temperature test chamber, which is regulated to better than ±0.3°C or within oven or high-precision incubators.

- pressure and flow-rates are precisely set or monitored using microprocessor-controlled syringe pumps

- Experiments are remotely controlled and test parameters recorded using customised code developed using the National Instruments LabVIEW™ software package.

Measured properties

- saturation and consolidation properties

- intrinsic permeability (including specific storage and anisotropy ratio)

- coupled flow parameters (e.g. osmotic permeability, consolidation coefficients)

- gas diffusion coefficients

- capillary entry breakthrough and threshold pressures

- gas permeability function

- drained and undrained compressibility

- rheological (creep) properties

- mechanical properties

Research interests

We have a considerable research track record in answering specific scientific questions relating to the safety case for deep geological disposal of heat-generating and high-activity radioactive wastes. This work has covered the flow and deformation properties of host rocks, engineered barrier systems and interfaces between engineering components.

- Led by Jon Harrington

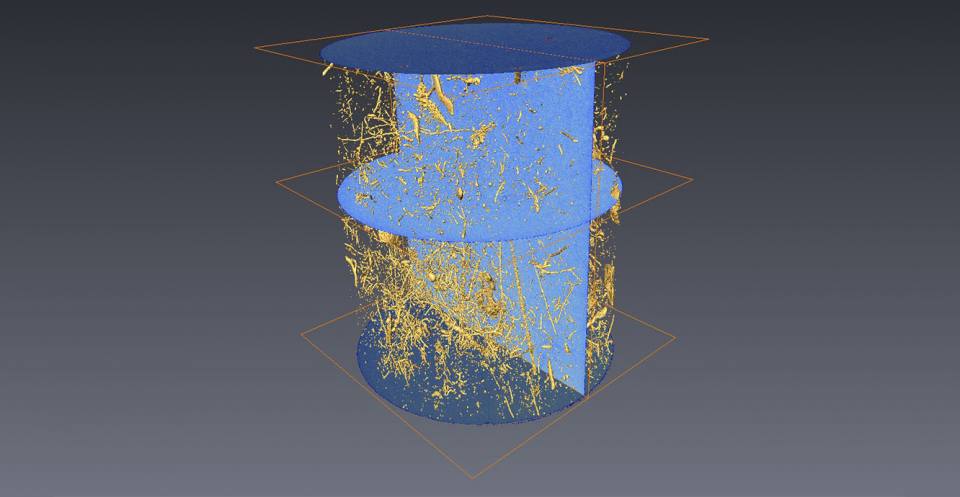

Our research focus has been on sealing properties of caprocks, reservoir rocks, and fracture and fault flow, with emphasis on changes in properties related to the depletion of reservoirs and the re-inflation resulting from injection of CO2.

- Led by Caroline Graham

Our shale gas research has focused on:

- permeability of individual units within prospective units of shale gas

- flow along fractures

- formation of hydraulic fractures

- composition of gas released by stimulation

Questions have been addressed for both exploration and regulator purposes.

- Led by Robert Cuss

Our research has focused on the mechanical controls on the formation of solution caverns created for underground gas storage and the permeability of salt formations. Emphasis has been placed on the cycling of cavern pressurisation and the influence this has on cavern integrity.

- Led by Jon Harrington

In close collaboration with the BGS’s Hydrothermal Laboratory, we conduct research on the flow properties of complex fault zones.

- Led by Robert Cuss

We conduct research that is complementary to the applied scientific areas. This includes:

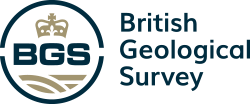

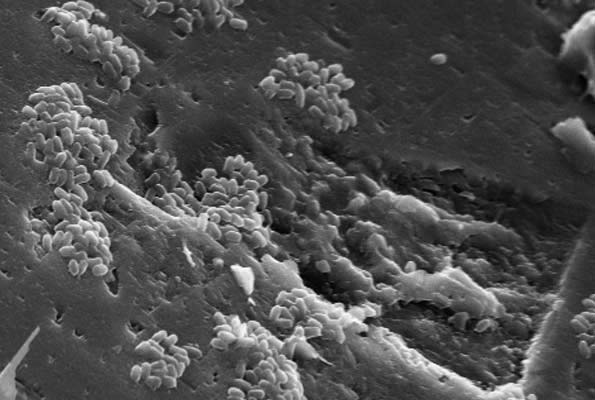

- visualisation of flow pathways

- manufacturing of synthetic rock samples

- flow at stress conditions not relevant to the specific applied areas

- development of novel experimental apparatus and techniques

- Led by Jon Harrington

Laboratory and field studies

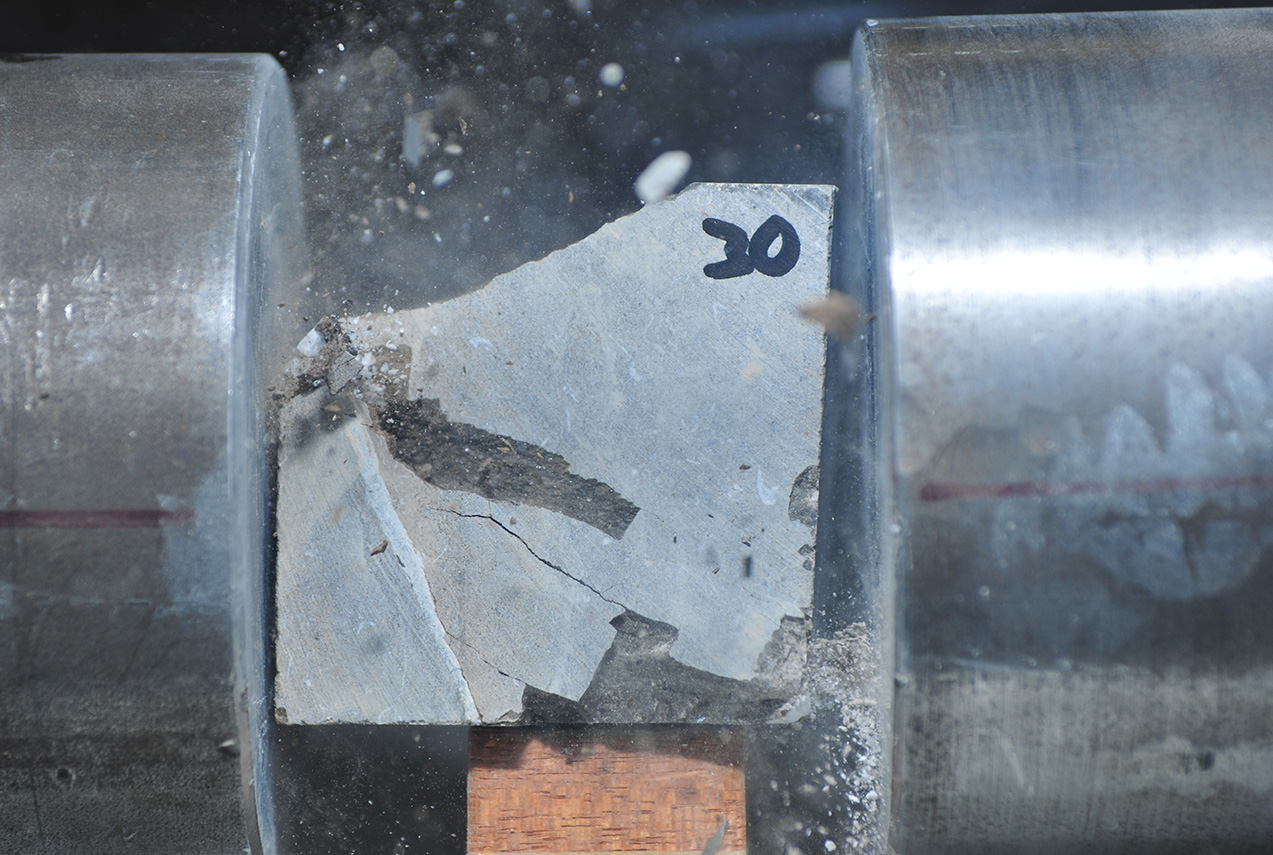

Rock mechanics testing: changes in flow properties in caprock under complicated pressure conditions. BGS © UKRI.

Laboratory capability

Laboratory research is conducted on samples up to 250 cc in size; these represent large test samples in low permeability materials. Tests can be conducted rapidly (in minutes), but our main emphasis is on long-term experiments that can run for multiple years. However, test durations of six months to one year are normal.

The laboratory has six isotropic, four constant volume, three shear rigs, and three triaxial apparatus. These cover stress conditions from 1 to 70 MPa (near surface to 3 km depth). The laboratory also has a high-pressure capability, which is able to extend the pressure range to 150 MPa (at 130°C) using an isotropic cell to explore flow and deformation behaviour at near-crustal depths.

The laboratory is also equipped with a number of hydraulic presses able to consolidate and condition-test material, or create synthetic samples for process understanding and material design. Pressures in excess of 500 MPa (on samples 60 mm in diameter) can be applied by the presses to yield materials with a range of material properties.

The TPRL has an established track record of the design, build and operation of field-scale investigations. These include the Lasgit experiment at the Äspö Hard Rock Laboratory (Sweden; 2005–2020), the gas transfer experiment at the Mont Terri Underground Research Laboratory (Switzerland: 2020–2022), and the cavern formation experiment at the Dark Matter Laboratory at the Boubly Potash mine (UK: 2019 onwards).

Further information

- laboratory studies examining gas, water and solute movement

- laboratory studies examining hydromechnical behaviour

- field-scale experiments examining gas and water flow in a range of natural and engineered systems

- preparation of state-of-the-art overview reports

- Eurad Gas and HITEC: specific outstanding questions of gas movement

- Beacon: bentonite mechanical evolution

- Cebama: properties of concrete/Callovo-Oxfordian claystone interface

- Lasgit: full-scale KBS-3 mock-up demonstrating gas behaviour

- Gas Transfer (GT): lab and field investigation of gas advection in Opalinus Clay

- M4ShaleGas: geological layers and fractures on the propagation of hydraulic fractures

- CONTAIN: role of depletion and inflation on caprock sealing

Need more information?

Relative topics

You may also be interested in

Science facilities

BGS operates and maintains a wide range of state-of-the-art laboratories and other facilities, which underpin virtually all of our research.

Fluid and Rock Processes Laboratory Cluster

Identifying, measuring and quantifying complex geological and environmental processes essential in the efficient utilisation of natural resources and underground spaces.