BGS is recognised as a European centre of excellence for the study of carbon dioxide (CO2) storage. We have a dedicated carbon capture and storage (CCS) team that is active in a number of research areas including:

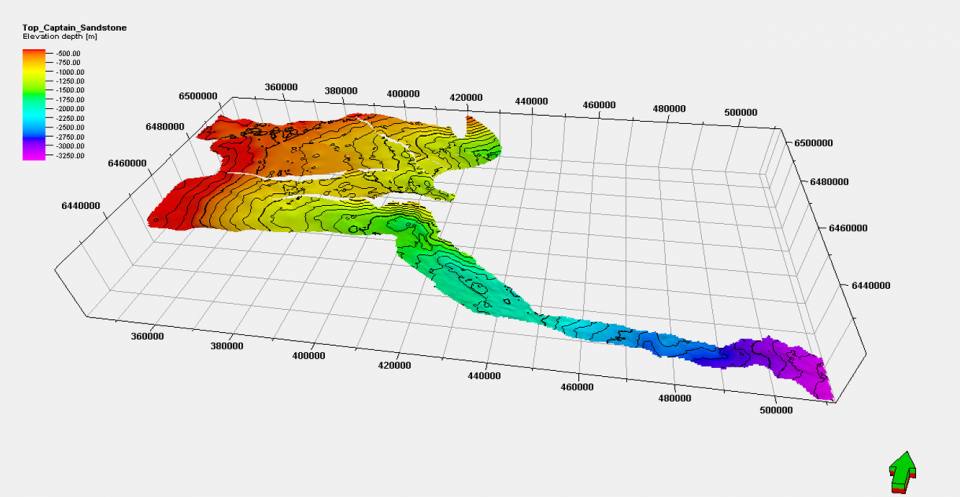

- characterisation and capacity estimation of potential underground storage reservoirs

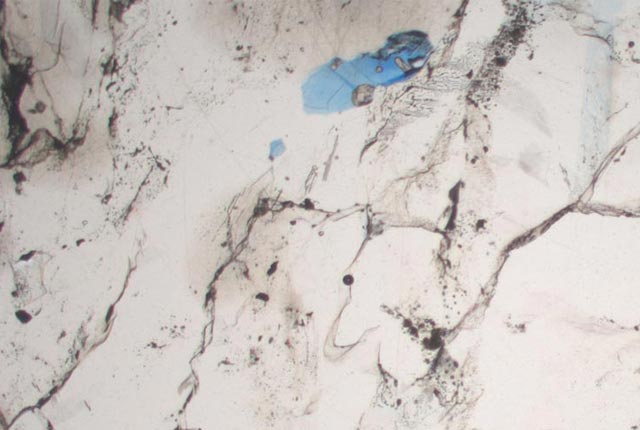

- potential chemical interactions of injected CO2 with the surrounding rocks

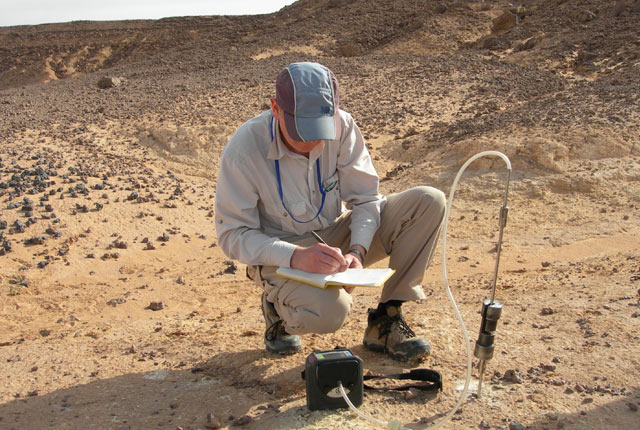

- storage site monitoring technologies and integrated monitoring strategies

- assessment of long-term site performance, including evaluating consequences of potential leakage

The coal-fired power station at Ratcliffe-on-Soar, Nottinghamshire. Power stations such as this emit million of tonnes of CO2 every year. © BGS/UKRI.

See our Discovering Geology pages for an introduction to carbon capture and storage.

Carbon capture and storage research at BGS.

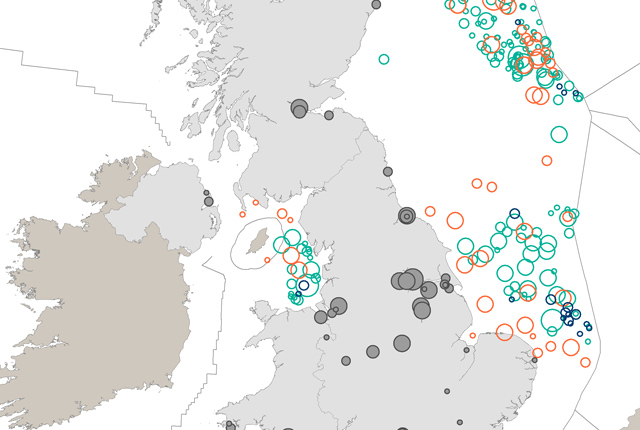

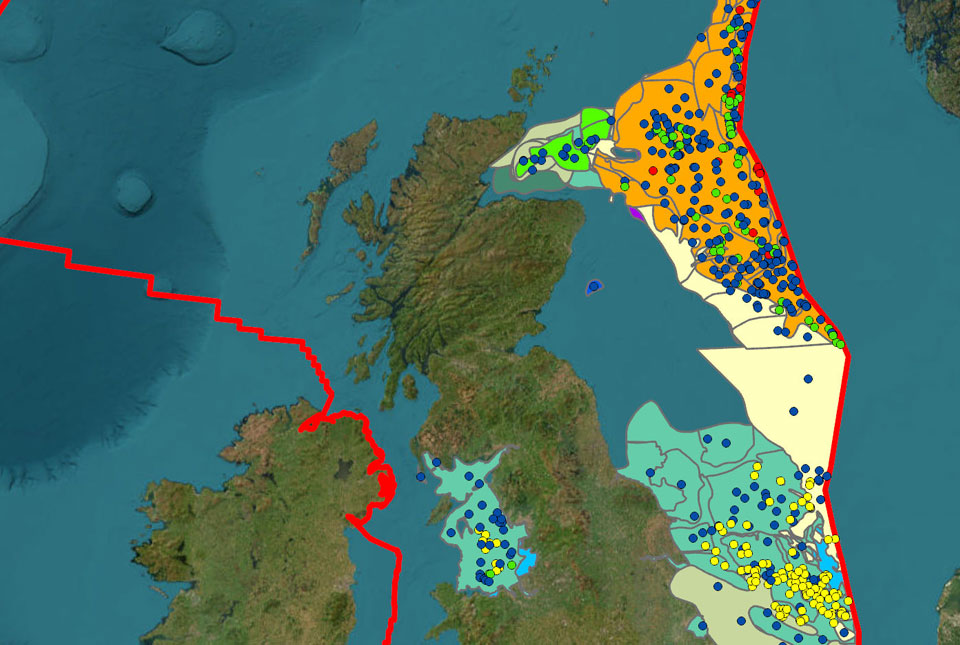

CO2 storage database

CO2 Stored is a national asset, identifying a geological storage potential of over 70 billion tonnes of storage deep under the UK seabed. The UK is the first country in the world to provide this information online. CO2 Stored is hosted and developed by the BGS in partnership with The Crown Estate.

Contact

If you want to discover more then please contact Jonathan Pearce.

Find out more about our research

CO2 storage capacity estimation

Providing a realistic, defensible and fully auditable estimate of the storage capacity of geological formations below the UK’s coastal waters assists in the licensing of CO2 storage sites.

CCS long-term performance

We are undertaking research that will help to ensure the safe and long-term storage of CO2.

CCS monitoring

Regulations require monitoring before starting operations at a CO2 storage site.

Carbon storage site characterisation

Successful storage operations require rigorous site characterisation focused on risk reduction for selected storage sites.

Related news

New funding awarded for UK geological storage research

21/11/2025

A project that aims to investigate the UK’s subsurface resource to support net zero has been awarded funding and is due to begin its research.

BGS hosts India for ‘deep dive’ on carbon capture and storage

30/07/2025

Some of India’s top scientists visited BGS to explore the UK’s carbon dioxide storage research potential.

Goldilocks zones: ‘geological super regions’ set to drive annual £40 billion investment in jobs and economic growth

10/06/2025

Eight UK regions identified as ‘just right’ in terms of geological conditions to drive the country’s net zero energy ambitions.

Could underground disposal of carbon dioxide help to reduce India’s emissions?

28/01/2025

BGS geologists have partnered with research institutes in India to explore the potential for carbon capture and storage, with an emphasis on storage.

BGS adds more than 60 new carbon dioxide storage units to its national carbon dioxide storage database

30/01/2024

BGS has delivered its first major update of the national carbon dioxide storage database, CO2 Stored.

Understanding long-term burial of organic carbon deposits

07/11/2022

Carbon sequestration is one method of reducing the amount of carbon dioxide in the atmosphere, by capturing and storing it, contributing to climate change reduction.

Identifying the science challenges for UK carbon storage

07/07/2022

A new report underlines importance of community engagement in achieving the UK national climate change targets.

Important new report outlines status of geological storage of carbon dioxide in Europe

22/12/2021

The latest news on the status of geological storage of carbon dioxide in Europe is outlined in a comprehensive new report from CO2GeoNet.

Standardised framework provides assessment of carbon dioxide storage site readiness

28/10/2021

Geoscientists have developed a practical framework for assessing the degree of ’readiness’ of a prospective carbon dioxide storage site.

Making recommendations for the management of carbon dioxide storage and unconventional hydrocarbon extraction sites

04/10/2021

The safe operation of geoenergy and subsurface storage sites is required to help meet net zero carbon ambitions.

BGS to help further carbon dioxide monitoring research at Sutton Bonington

03/08/2021

BGS is part of a research project that will consider the feasibility of using quantum gravity sensors to monitor carbon capture and storage sites.

BGS part of successful Energy Research Accelerator to put Midlands region on the road to net zero

08/06/2021

The consortium of internationally-recognised research institutions will bring together expertise in energy research to help the UK to meet its ambitious net zero targets

You may also be interested in

Hydrocarbon systems

Working with UK and overseas governments to provide geological and oil prospectivity advice.

Energy storage

Continuing BGS’s sustained track record of energy storage research, which will underpin future laboratory, field and GIS-based activities and commissions.