Research undertaken within BGS may require unique equipment that is not available commercially, often because the application is entirely novel and provides an innovative solution. The Research and Design Engineering Facility fills this gap with its conceptualising, designing, testing and manufacturing services based on the BGS campus at Keyworth.

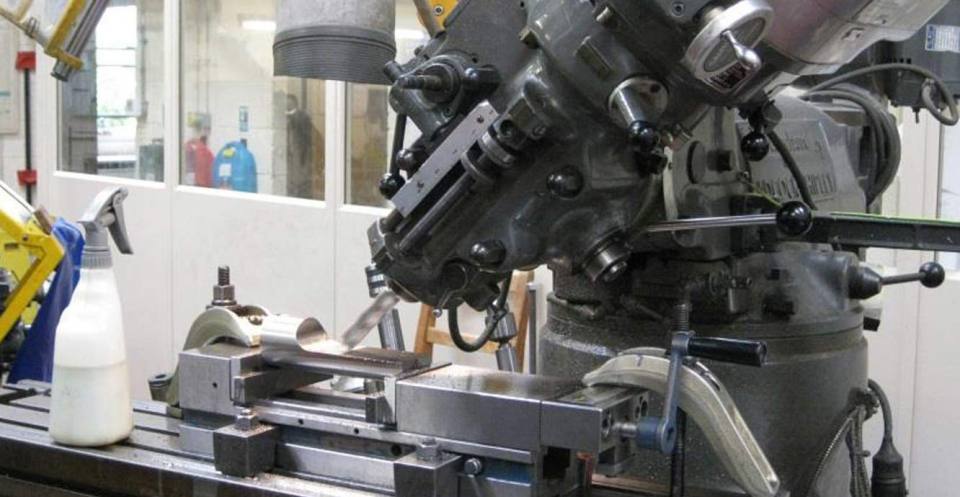

Forming curved faces on an angled milling machine. BGS © UKRI.

Our services

The R&D Engineering Facility incorporates the following capabilities:

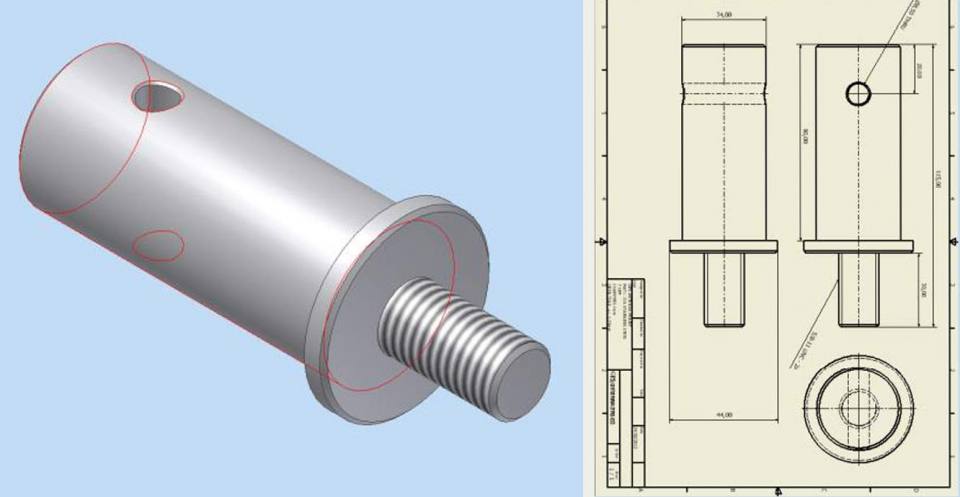

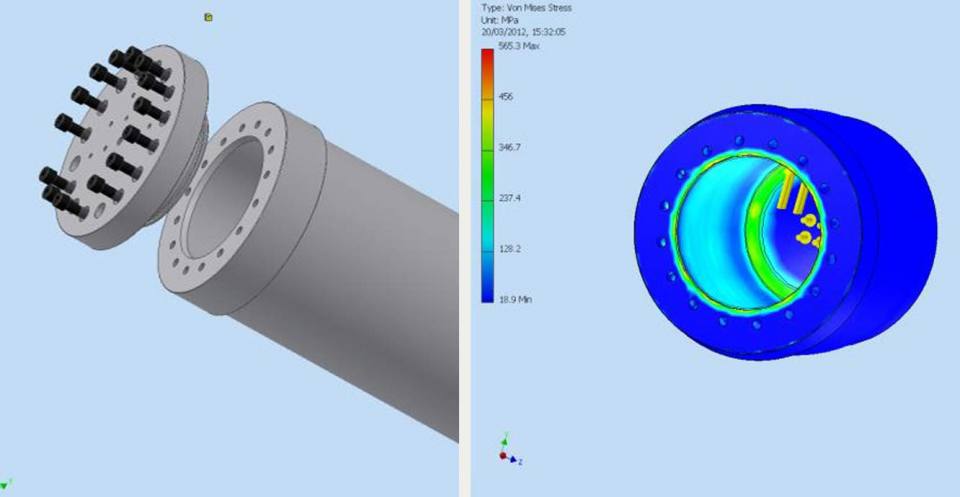

- 3D modelling package (Autodesk Inventor): this software is used as a design tool at several other NERC technical facilities. It has a powerful FEA capability and graphics that are suitable for posters and technical reports. Drawings can be emailed in all industry standard CAD files.

- Tool room type workshop: turning, milling, surface and cylindrical grinding, and hand fitting.

- Fabrication tools: horizontal and vertical band saws suitable for all materials, sheet metal guillotine, folders and rollers.

- Welding bay: equipped with MIG, TIG, spot, and MMA welding. Oxyacetylene, brazing and silver soldering. Ability to weld most common materials (including some plastics).

- Joinery and wood machine shop: equipped with band saw, circular saw, planer thicknesser, disc and bobbin sander.

- Material and consumable parts storage and procurement: in-house storage of common metals and plastics in sheet, rod and bar form; rapid procurement of special materials and forms.

Case studies

- A low-cost solution to mount GPS antennae to scaffold poles driven or concreted into the ground

- Corrosion resistant

- Product lifespan: two years operation in subzero temperatures (Iceland)

- Assembled without specialist tools in the field

- Discuss requirements and suggest small changes to original concept to provide better weathering and easy assembly. Suggest manufacture of jig to drill scaffold tubes in the field.

- Design and model prototype.

- Finalise engineering design and order material.

- Manufacture.

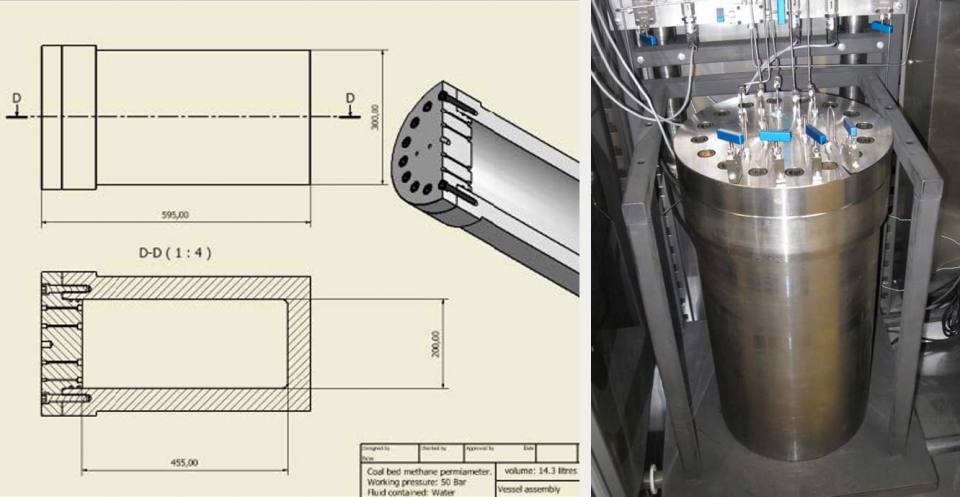

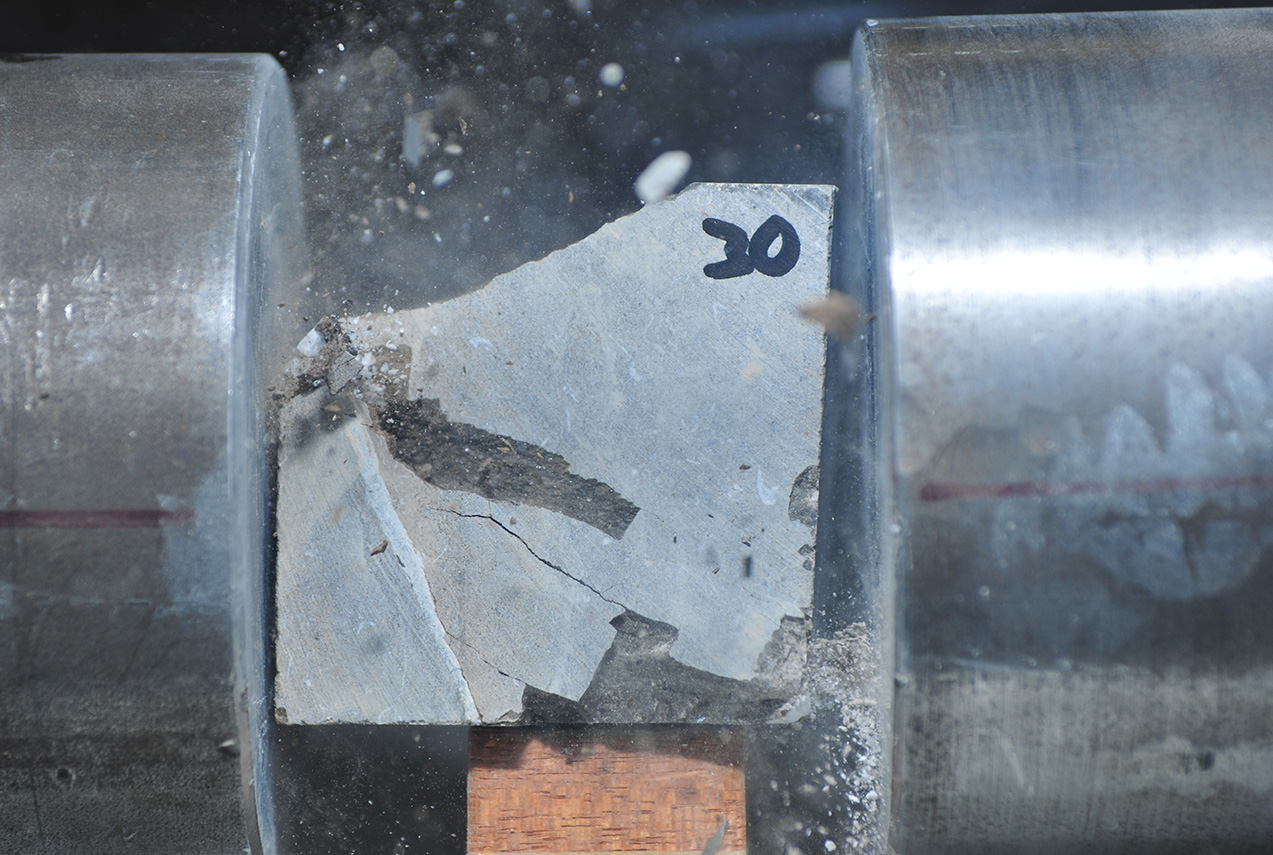

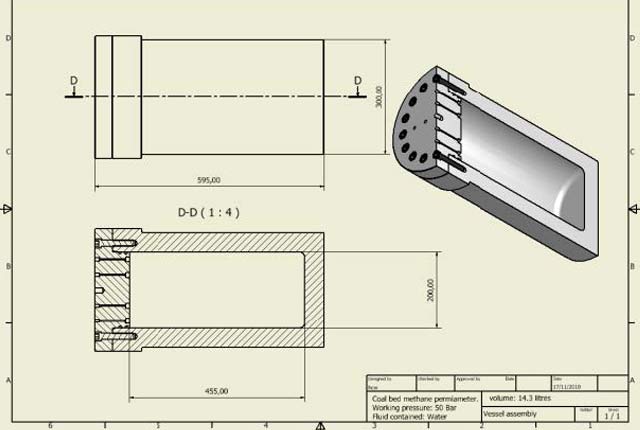

- A 15-litre vessel to contain a confining fluid for gas permeability tests on coal

- Corrosion resistant

- Working pressure 50 bar

- Contain a 150 mm diameter core

- Meeting with project leader to discuss feasibility.

- Evaluate steps for compliance with pressure vessel directive.

- Design and model prototype. Order materials.

- Find manufacturer to machine body.

- Pressure test, certificate.

Step 6 Install.

Relative topics

Need more information?

You may also be interested in

Science facilities

BGS operates and maintains a wide range of state-of-the-art laboratories and other facilities, which underpin virtually all of our research.

Engineering and Geotechnical Capability

Leading the development and application of field and laboratory infrastructure and long-term management of geophysical and geotechnical property data.