The BGS Drilling Facility operates out of BGS Keyworth. The drilling team is comprised of staff from different science areas across BGS, all trained to an in-house level as either lead driller or assistant driller status. The facility has been in operation since the end of 2005 and uses a Dando Terrier 2002 rig to perform shallow drilling to depths of 10–15 m.

Core recovery methods

The drill rig has three methods of recovering core depending on the geology being drilled.

The percussion mode is the main method used for the majority of situations. This method uses a drop hammer to drive a barrel into the ground in 1 m intervals to collect a full sample of the geology. The core is recovered in a plastic liner contained inside the barrel, which allows inspection of the core in the field.

The percussion method can use four barrel sizes, which provide core of 117 mm, 102 mm, 87 mm and 75 mm.

The method is suitable if you want to drill:

- firm to indurated deposits, e.g. tills to weak mudstones

- sand and gravel deposits

- firmer mudstone deposits, e.g. Oxford Clay

- soft, unconsolidated sediments, e.g. estuarine silts and clays, peats

Opaque liners can be obtained if you require photoluminescence analysis, for example.

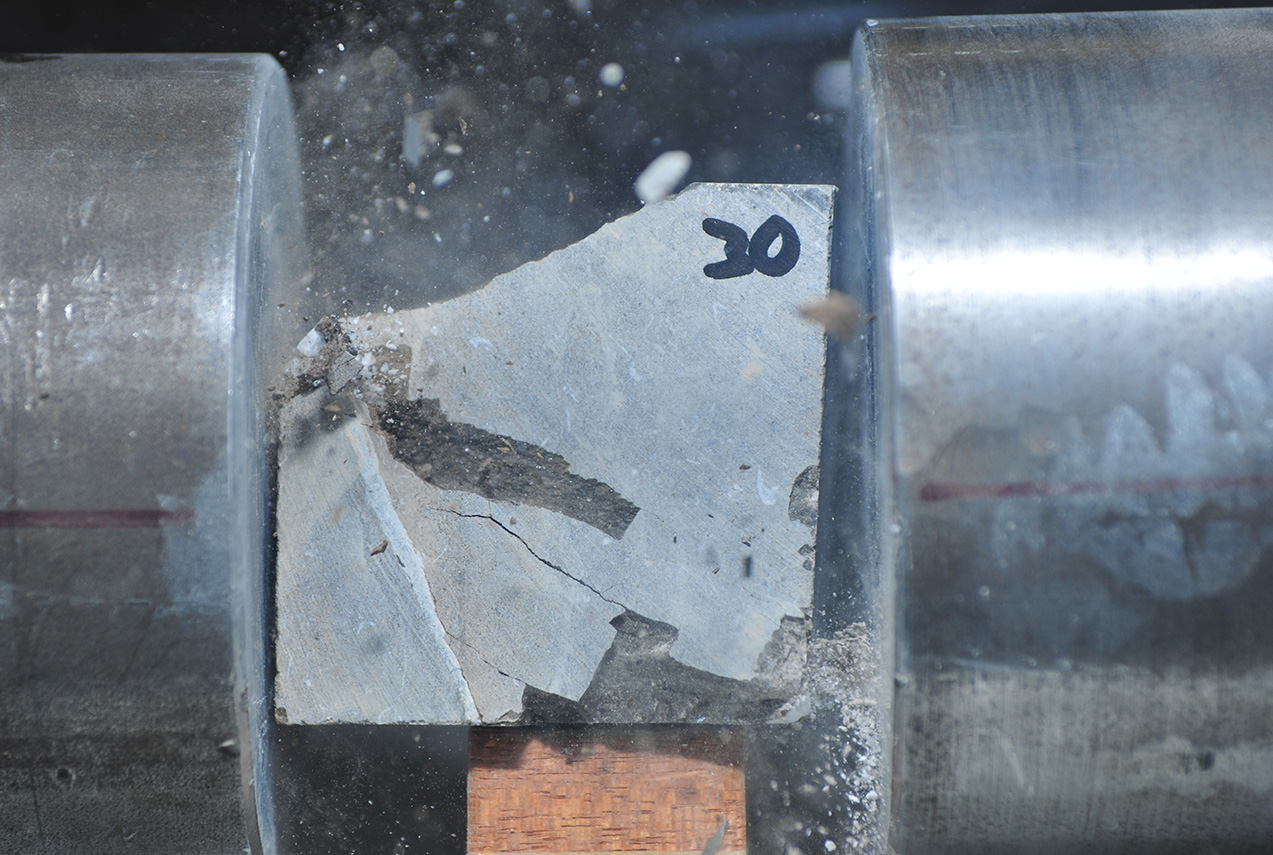

The rotary corer is used for drilling harder materials. This method uses a rotary head and cutting bits on the barrel head to provide cores from rocks such as sandstone and limestone. The material is recovered in a plastic liner as in the percussion method, but the barrel is rotated into the ground under the weight of the drillhead.

This method returns a core sample of 84 mm in a plastic liner. The rotary corer is slightly slower than the percussion method and can be used for drilling indurated to well-indurated deposits, e.g. tills, mudstones, siltstones, sandstones.

The rotary augering method uses the rotary head with a selection of augers to core into softer sediments. The hollow-stem auger produces a larger bulk sample than a continuous flight auger.

Neither of these augering methods provides a core encased in a plastic liner, but usually recover material as bulk samples.

This method is suitable if you want to drill sand and gravel deposits or estuarine deposits with sand and gravel.

Research

The BGS Drilling Facility has been involved with a number of research themes. These have ranged from drilling estuarine sequences in the Thames basin looking at the depositional evolution of the River Thames to coring various glacial till deposits in Wales and trying to understand the deposition of basement till, glacial lake sediments and moraines. We have been involved with providing sample and installing piezometers at a test site on the River Trent floodplain to understand the groundwater response to rainfall. We have also played a large part in the re-mapping process of certain areas of the UK such as the Cretaceous of the Isle of Wight, the Jurassic in Oxfordshire and Quaternary deposits in Somerset.

Further improvement of our in situ downhole drilling tests means that the team now has the capability to perform standard penetration tests, cone penetration tests and dynamic probe tests. This has been used to determine the strength characteristics of landslides.

Drilling services

The team aims to provide a complete service and if necessary can provide additional services to a project. In particular the team have developed skills and contacts in:

- searching for utilities and cables

- organising the field site

- recording all drilled core as a standard driller’s log (to BS5930)

- remediation of the site after drilling has been completed

- transfer and storage of all cores back to BGS Keyworth

- registering of boreholes and logs in the BGS system

- performing downhole tests and completing piezometer installation if necessary

Relative topics

You may also be interested in

Science facilities

BGS operates and maintains a wide range of state-of-the-art laboratories and other facilities, which underpin virtually all of our research.

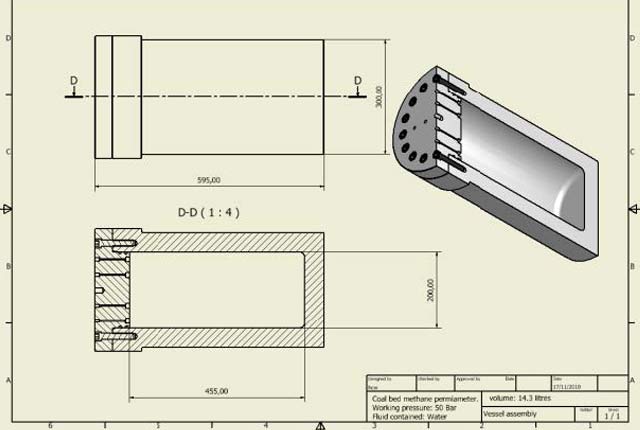

Engineering and Geotechnical Capability

Leading the development and application of field and laboratory infrastructure and long-term management of geophysical and geotechnical property data.